Ouyang Minggao: R&D and Prospects of China's New Energy Vehicles

- Categories:Media Coverage

- Author:

- Origin:

- Time of issue:2015-03-28

- Views:0

(Summary description)In recent years, China's new energy vehicles have developed rapidly and have become a bright spot in technological innovation and industrial upgrading. This paper summarizes the technological progress and industrialization of new energy vehicles supported by the National Science and Technology R&D Program, and looks forward to the focus of new energy vehicle technology research and development in the next five years.

Ouyang Minggao: R&D and Prospects of China's New Energy Vehicles

(Summary description)In recent years, China's new energy vehicles have developed rapidly and have become a bright spot in technological innovation and industrial upgrading. This paper summarizes the technological progress and industrialization of new energy vehicles supported by the National Science and Technology R&D Program, and looks forward to the focus of new energy vehicle technology research and development in the next five years.

- Categories:Media Coverage

- Author:

- Origin:

- Time of issue:2015-03-28

- Views:0

The original text was published in Science and Technology Herald 2016, Volume 34, Issue 6, Special Issue on New Energy Vehicles Author: Professor Ouyang Minggao

Summary

In recent years, China's new energy vehicles have developed rapidly and have become a bright spot in technological innovation and industrial upgrading. The breakthrough of core technology has led to the improvement of product performance, and the implementation of incentive policies has promoted the process of industrialization . This paper summarizes the technological progress and industrialization of new energy vehicles supported by the National Science and Technology R&D Program, and looks forward to the focus of new energy vehicle technology research and development in the next five years.

Key words: new energy vehicle electric vehicle industrialization

Since the beginning of the 21st century, China's auto industry has achieved rapid development, and its industrial scale has ranked first in the world for many consecutive years. At the same time, the number of car ownership has also risen rapidly, has exceeded the 150 million mark, and is expected to reach about 250 million by 2020. While the automobile industry has become a pillar industry of the national economy and an important symbol of national prosperity, China is also faced with major problems such as a large but not strong automobile industry, as well as increasingly serious automobile exhaust pollution and oil safety.

Automotive energy and environmental issues are also huge challenges faced by the global automotive industry in the 21st century. Global low-carbon development goals and increasingly stringent fuel consumption regulations objectively require the transformation and upgrading of vehicle energy and power systems as soon as possible.To this end, the global automotive power system technological change has been triggered: various energy-saving and environmentally friendly vehicles featuring clean vehicle emissions, vehicle fuel conservation, and vehicle energy diversification have developed rapidly, and hybrid and pure electric vehicles have achieved industrialization. Fuel cell vehicles have entered the market, and core technologies such as power batteries and fuel cells have continued to break through and upgrade. It indicates that the first 20 years of the 21st century will be a period of strategic opportunity for the transformation of automotive energy power systems.In the medium and long term, in order to achieve the global greenhouse gas emission reduction target in 2050, the global energy structure will also undergo major adjustments, and the centralized supply energy system dominated by fossil energy will be transformed into a clean and renewable energy dominated, distributed and centralized supply. A new model of combined energy network. New energy vehicles, represented by plug-in hybrid electric vehicles, pure electric vehicles and fuel cell vehicles, will become an important part of the new world economic system as the terminal of energy consumption, energy storage and energy return in the energy network. Fundamentally solve major problems such as air pollution, energy security, and low-carbon development.

The technological transformation of global automotive energy and power systems has provided China with a historical opportunity. At the same time, China also has a unique development environment and advantages. The structure of China's transportation system has obvious characteristics of "point-line-surface" : big cities and large urban agglomerations are "points", the main traffic roads connecting large cities are "lines", and the vast small and medium-sized towns and rural areas are "surfaces". On the "point", the bus system dominates, and the electrification of public transport vehicles leads the world; on the "line", the railway dominates, and the electrification of high-speed rail leads the world; on the "face",short-distance transportation dominates, and electric bicycles lead the world.In this transportation system, China's passenger vehicles are mainly driven in urban areas, with the characteristics of short-distance travel. In addition, China's institutional advantages in road traffic construction and management, on the basis of the existing transportation electrification, China's new energy electric vehicles Great potential to develop global leadership.

The Chinese government attaches great importance to the development of new energy vehicles and has established it as a national strategy. The development of China's energy-saving and new energy vehicles has undergone research and development, demonstration and assessment under the support of the national science and technology plan since the "Tenth Five-Year Plan". The sales volume has exceeded 300,000 units, ranking first in the world. This paper briefly summarizes and looks forward to the research and development progress of new energy vehicles in China.

1 New energy vehicle technology research and development process

China has carried out large-scale and organized research and development of electric vehicle technology since the "Tenth Five-Year Plan". The "Tenth Five-Year Plan" period is the stage of laying the foundation for China's new energy vehicles, and organized the implementation of the national "Tenth Five-Year" major scientific and technological projects for electric vehicles; Implemented the "Eleventh Five-Year Plan" and "863 Plan" major projects of energy saving and new energy vehicles; during the "Twelfth Five-Year Plan" and "863 Plan" major projects of energy saving and new energy vehicles; Year Plan" period, China's new energy vehicles from the demonstration assessment to the industrialization start stage, organized the implementation of the "Twelfth Five-Year" electric vehicle key projects special.

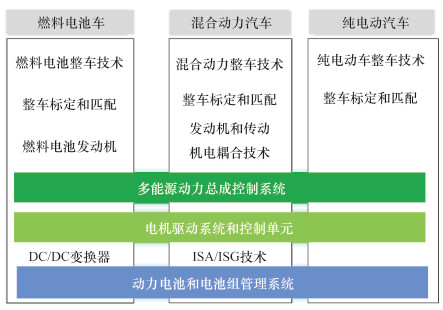

1.1 "Tenth Five-Year" Electric Vehicle Major Project

In the context of the rapid development of China's auto industry, the backwardness of traditional auto technology, and the starting line of electric vehicles and foreign countries, in order to occupy the commanding heights and gain a favorable position in the new round of competition in the world auto industry, and improve the international competitiveness of China's auto industry, thus To achieve the leap-forward development of China's auto industry, in 2001, with the approval of the National Science and Education Leading Group, China implemented the National Electric Vehicle Major Science and Technology Project [1].The major electric vehicle project focuses on the development of vehicle technology and key component technology. It adopts the model of vehicle leadership, component cooperation, and industry-university-research integration. According to the characteristics of vehicle products and the shared attributes of key core systems, an electric vehicle is established. The matrix R&D layout of "three verticals and three horizontals" for automobiles [2] (Figure 1).

Figure 1 "Tenth Five-Year Plan" Electric Vehicle Major Science and Technology Special Layout

"Three verticals" refer to three complete vehicles of fuel cell vehicles, hybrid electric vehicles and pure electric vehicles. "Three horizontal" refers to the three key components system, such as power battery, drive motor, and multi-energy powertrain electronic control.In the "three vertical and three horizontal" R&D layout, the vehicle project unit is fully responsible for the quality, progress and capital utilization of the vehicle at each stage and the overall goal, realizing the optimal combination of research topics for assemblies, subsystems and parts, Coordination, guidance, and monitoring, thus forming a vertical sub-alliance of the industrial chain; at the same time, in order to enable the "horizontal" to unite and communicate, cultivate three common parts and industrial chains for the whole vehicle , and establish battery, motor, and electronic control 3 respectively. A special group is responsible for coordinating the technical indicators of the parts system, establishing an evaluation and technical standard system,and simultaneously carrying out coordinated development of safety and reliability.

Through the investment of national scientific research funds during the "Tenth Five-Year Plan", more than 200 enterprises, universities and research institutes have formed a research and development team composed of more than 2,000 technical backbones in China, trained a group of young and middle-aged technical backbones, and established China's electric vehicles. The talent team urgently needed for industrial development has promoted the introduction of 26 national standards; a total of 796 domestic and foreign patents have been applied for. The implementation of the special project has played an important role in enhancing the core competitiveness of China's auto industry, achieving key leaps, and laying a technical foundation for the industrialization of electric vehicles [3].

1.2 "Eleventh Five-Year" energy-saving and new energy vehicle major projects

With the release of the "National Medium- and Long-Term Science and Technology Development Plan (2006-2020)"[4], with one of the priority themes "low energy consumption and new energy vehicles" and one of the cutting-edge technologies "hydrogen energy and fuel cell technology" In response to this, the overall R&D idea of the Eleventh Five-Year Plan is to promote the parallel interaction and coordinated development of energy-saving and new energy vehicles based on the strategic research results in the field of transportation and energy in the national medium and long-term scientific and technological development plan [5, 6]. On the one hand, optimize the existing vehicle energy power system based on internal combustion engine to develop energy-saving vehicles; on the other hand, develop a new generation of vehicle energy power system and develop new energy vehicles. Through the dual strategy of "transition" and "transformation", it promotes the dual technological change of vehicle power electronic control and electrification. Under the basic framework of "three verticals and three horizontals", the overall layout of R&D has expanded accordingly in terms of the "three verticals" of models. Comprehensive consideration of fuel cell vehicles, pure electric vehicles and extended-range electric vehicles based on electric energy.

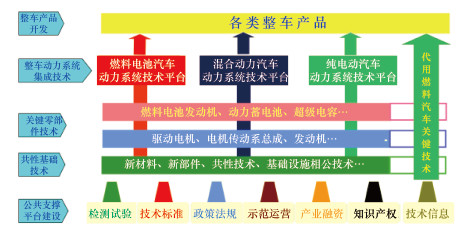

The R&D layout of major energy-saving and new energy vehicle projects during the Eleventh Five-Year Plan is shown in Figure 2 [7]. The project is based on the research and development achievements of the "10th Five-Year Plan" electric vehicle major science and technology project and the clean vehicle science and technology action plan, and aims to "establish a technology platform, make breakthroughs in key technologies, and achieve technological leapfrogging", "establish a research and development platform, form standards and norms, and create an innovative environment" And "establishing a product platform, cultivating an industrial ecology, and promoting industrial development" as the three core goals, 270 projects have been arranged in key components, power systems, vehicle integration, test platforms, demonstration and promotion, and standard policy research. Vehicle integration is the carrier and power system is the core, focusing on breaking through the bottleneck technology of key components and supporting industrialization demonstration and promotion. 14,600 scientific and technical personnel from 432 units including domestic vehicle and parts enterprises, research institutions, universities and colleges participated in the research and development work, and established a joint research and development innovation system of China's electric vehicle industry, academia and research.

Figure 2 Layout of major energy conservation and new energy vehicle projects during the Eleventh Five-Year Plan

Through the implementation of the National Science and Technology Plan for 5 years [8], a large number of key technologies for energy-saving and new energy vehicles have been conquered. More than 350 types of new energy vehicles have entered the national vehicle announcement catalog, and there are more than 19,000 self-developed vehicles in 25 demonstration cities. Demonstration and application of electric vehicle products; breakthroughs in a number of key technologies for alternative fuel vehicles, leading to the formation of 1.4 million natural gas vehicles in China; combined with the 2008 Beijing Olympics and the 2010 Shanghai World Expo and other international large-scale events, successfully carried out centralized, The high-intensity electric vehicle demonstration operation has achieved good international influence; 59 national and industry standards for electric vehicles have been formulated to basically meet the needs of electric vehicle technology research and development and industrialization; 15 national key laboratories and engineering technology research centers have been established to form There are 48 electric vehicle R&D platforms; the project results have won 10 second prizes of the National Science and Technology Progress Award, and 22 first prizes of the provincial and ministerial science and technology progress awards; accumulatively applied for 2011 patents, including 1015 invention patents.

1.3 "Twelfth Five-Year" electric vehicle key projects

During the "Twelfth Five-Year Plan" period, the development of China's new energy vehicles is faced with more urgent strategic needs. First, as one of the national strategic emerging industries, new energy vehicles bear the needs of automobile technology transformation [9], and secondly, the national automobile energy conservation and environmental protection regulations The demand for industrial upgrading brought about by continuous strictness [10]. On the basis of listening to the opinions of experts many times, the national leaders started from the speech of General Secretary Hu Jintao at the academician conference of the Chinese Academy of Sciences and the Chinese Academy of Sciences in 2010[11] and the speech of General Secretary Xi Jinping on new energy vehicles in 2014 as the mark[12] , the rise of electric vehicles as a national strategy.

In this context, the Ministry of Science and Technology has formulated the “Twelfth Five-Year Plan for the Development of Electric Vehicle Technology”[13]. Technological transformation is the overall strategy, and the technological development path of "integration" of technology platforms, "two ends squeezed" in model development, and "three-step" industrial promotion is proposed. Prioritize the development of "pure electric drive" electric vehicles in urban public vehicles and private small cars to form a development pattern of "crowding at both ends" and start the market. Then it will develop in a rolling way, gradually occupying the market space of mid-to-high-end sedans. The organization and implementation of the project implements the spirit of the State Council's 2010 "Decision on Accelerating the Cultivation and Development of Strategic Emerging Industries", and has become a major scientific and technological measure for cultivating and developing strategic emerging industries of new energy vehicles.

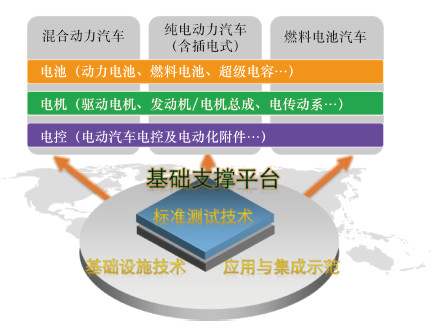

In terms of R&D layout, on the basis of "three verticals and three horizontals", we will further strengthen the transformation of pure electric drive technology. In terms of "three verticals", pure electric vehicles, extended-range electric vehicles and plug-in hybrid electric vehicles are the mainstays of pure electric drive vehicles. The basic types are classified into a large category; fuel cell vehicles, as a special type of pure electric vehicles, continue to be independent as a "vertical"; hybrid vehicles are mainly conventional hybrid vehicles. In terms of "three horizontals", batteries include power batteries and fuel cells; motors include motor systems and their integration technology with engines and gearbox assemblies; electronic controls include electric steering, electric air conditioning, electric braking, etc. Automotive electronic control system technology. At the same time, in order to meet the needs of transformation from scientific and technological research and development to demonstration and promotion, the research and development of three supporting platforms including standard testing, energy supply, and integrated demonstration have been added, thus forming the strategic focus and task layout of "three horizontal and three vertical platforms" (Figure 3). ).

Figure 3 "Twelfth Five-Year" electric vehicle key special layout

In terms of organization and implementation, according to the different stages of technological development of "three verticals" (hybrid power, pure electric drive, fuel cell), the "three verticals" are established with "industrial chain", "value chain" and "technical chain" as links respectively. The "Three Chain" Technology Innovation Alliance conducts research and development activities. There are 61 special deployment projects, including 18 863 projects, 36 science and technology support plan projects, 3 international cooperation projects, and 4 public welfare projects. 177 universities and research institutes across the country participated. As of 2015, the first batch of start-up projects that have been accepted have completed more than 500 new products, new processes and related software development, published more than 1,000 scientific papers, and applied for more than 1,000 domestic invention patents. The implementation of the special project has comprehensively driven the development of the entire industrial chain of key components, complete vehicles and supporting platforms, and the technology has supported the industrialization of China's new energy vehicles, ranking first in the world in 2015.

2 Advances in New Energy Vehicle Technology

After three five-year scientific and technological breakthroughs, China has mastered the complete vehicle technology of new energy commercial vehicles and realized the transition from hybrid to pure electric drive; it has developed a unique pure electric drive technology for new energy passenger vehicles The route has achieved leap-forward development of technology; fuel cell vehicles have formed independent research and development capabilities and achieved basic synchronization with international technologies; in terms of key components, lithium-ion vehicle power battery technology and motor drive system technology have made significant progress; In terms of public platform technology, a new energy vehicle standard system and a vehicle, battery, and motor test platform have been established.

2.1 Technology of key components

1) Power battery technology. So far, China's electric vehicle power battery research and development has gone through three stages. "Tenth Five-Year" initial stage: mainly develop nickel-hydrogen power batteries and lithium manganate lithium-ion power batteries; "Eleventh Five-Year" development stage: increase the research and development of lithium iron phosphate batteries, support the "Twelfth Five-Year" electric vehicle demonstration and Industrialization; "Twelfth Five-Year" upgrade stage: focus on supporting the research and development of ternary material power batteries, and the specific energy target of the battery is required to reach 180 (W·h)/kg. After three five-year plans, China has basically mastered core technologies such as battery materials, single cells, battery systems, and mass production processes. China has formed a complete battery material technology system including lithium iron phosphate and lithium manganate cathode materials, ternary material precursors, graphite anode materials, lithium titanate anode materials, electrolytes and PP/PE separators. Basic sync. China has made important breakthroughs in the design and manufacturing capabilities of single cells, and the energy density of batteries has been significantly improved. For example, the energy density of lithium iron phosphate cells has increased from 90 (W·h)/kg in 2007 to nearly 140 (W·h)/kg , the energy density of the battery cell of the ternary material reaches 180 (W·h)/kg, which is basically in sync with the international level; the specific power of the power battery reaches 3000 W/kg, which is comparable to the international advanced level. China has made great progress and breakthroughs in battery system integration technology and capabilities. The specific energy of power battery modules can reach a maximum of 140 (W·h)/kg or more, and the industrialization technology level of lithium-ion power batteries has been able to support large-scale development of electric vehicles. Technical and industrial conditions for commercial operation. However, there is still a gap between China and the international leading level in basic research such as advanced battery materials and mechanisms, as well as battery consistency and yield.

2) Motor drive technology. In terms of drive motor technology, the multi-domain integrated optimization design concept of automotive motors is adopted to solve technical problems such as limit design, multi-physics accurate analysis, control strategies, and system integration of multi-objective high-performance automotive motors. The structural integration design technology is adopted to realize the highly integrated design and application of the motor and the transmission in the mechanical, electromagnetic and thermal fields. Taking advantage of China's rare earth resources, the technical characteristics of permanent magnet motors for vehicles have gradually formed. Many motor companies in China have made breakthroughs in the design and manufacturing technology of high-efficiency and high-power density permanent-magnet motors for vehicles, and developed high-speed motors with a power density of over 3 kW/kg. High-density permanent magnet motors have been widely used in a variety of pure electric cars and plug-in hybrid cars. Chinese commercial vehicle motors (especially direct drive motors) already have strong international competitive advantages in terms of torque indicators and cost control.

In terms of motor controller technology, power electronic module integration technology is adopted to highly integrate automotive-grade IGBT modules, long-life film capacitors and low-inductance composite busbars, low thermal resistance heat dissipation technology, and miniaturized circuit board design technology. The volume and weight of the controller improves the system integration and realizes the integration of power electronics and information processing technology. The power density of a typical motor controller in China reaches 8 kW/L, the peak efficiency of the controller exceeds 97%, and the high-efficiency area greater than 90% exceeds 50%. The torque control accuracy in the full speed range is improved to ±2~3 N m or ±3%~5%. However, there is still a gap between China and the international leading level in chip integrated design and power electronic system integration.

3) Vehicle fuel cell technology. The fuel cell system technology chain is long, and China's related foundation is weak. After years of hard work, China has made remarkable progress in fuel cell electrochemical basic material devices and stacks. In recent years, breakthroughs have been made in durability-enhanced composite membranes, high-activity anti-toxic catalysts, high-conductivity carbon paper, and low platinum loadings. During the "Twelfth Five-Year Plan" period, China has basically broken through the design technology of metal bipolar plate stacks, and the developed sample stack power density Breaking through the level of 2 kW/L has laid the foundation for the research and development of high power density engines in the future. The developed fuel cell catalysts, composite membranes, carbon paper, membrane electrodes and bipolar plate samples can meet the needs of commercialization in terms of performance indicators, but it is necessary to establish a mass production line, vigorously carry out testing and evaluation, and establish a related industrial chain to promote China's fuel economy. The battery technology catches up with the international advanced level.

4) Electric accessory technology. Electric air conditioner: Developed the inverter compressor motor control technology without position sensor, the high-efficiency integrated low-noise electric air conditioner technology, and the high-efficiency control technology of the electric air conditioner based on the bus control technology, realizing the integrated thermal management of the air conditioner and the battery.

Electric steering: Breakthrough in key technologies of electronically controlled power steering systems such as steering sensor, EPS controller, EHPS controller, matching between EPS and electric cars, and matching between EHPS and electric buses. The electronically controlled power steering system works normally in the range of -40 to 85 °C, and has good high and low temperature stability.

Electric braking: On the basis of China's existing independent technology of hydraulic and pneumatic ABS systems, through integrated design, the energy feedback hydraulic and pneumatic braking system has been successfully developed, breaking the international monopoly and having a competitive advantage in cost . The comprehensive optimization of braking safety, system reliability and life, braking comfort and braking energy recovery efficiency is realized. The contribution rate of regenerative braking to energy economy is over 20%.

2.2 Vehicle Technology

1) Pure electric vehicle technology. Pure electric vehicles are the main type of new energy vehicles in China. After the efforts of three five-year plans, China's pure electric passenger vehicle technology has made significant progress, the overall technical level is close to the international advanced level, the driving range, reliability and safety have been continuously improved, and energy efficiency has been continuously optimized. It is fully equipped for commercialization. condition. In particular, it has formed the technical characteristics of small pure electric cars with Chinese characteristics.

The overall technical level of pure electric buses has reached the international advanced level. A pure electric bus design theory and system integration system has been established; significant progress has been made in high-efficiency electric drive system, vehicle lightweight, power source thermoelectric integration and management technology, etc. The standardization of electromechanical interfaces has established a technology platform for new energy buses, and developed an electrified chassis for low-floor buses. The vehicle developed based on the platform has excellent performance. The actual power consumption of a 12-meter bus for 100 kilometers is about 100 kW·h.

In terms of electric vehicle charging and swapping facility technology, a simulation platform for electric vehicle charging and swapping facilities has been established; the interface technology of charging and swapping equipment with various conversion capacities based on AC and DC energy supply modes, charging and swapping process control technology, electric energy Metering technology, safety and reliability technology; developed 40 kW single-port three-phase AC on-board charging technology and 450 kW DC off-board charging technology and products; the new battery replacement technology can replace 11 boxes of batteries within 3 minutes. Developed a prototype of the wireless charging system and started to demonstrate it on the vehicle.

2) Plug-in hybrid vehicle technology. In terms of passenger vehicles, China has basically mastered the core key technologies such as hybrid electromechanical coupling, hybrid dynamic coordinated control and energy management systems. Formed the P3 rear-parallel hybrid system represented by BYD Qin and the four-wheel drive hybrid system developed on this basis; the dual-motor series-parallel hybrid system represented by SAIC Roewe 550, jointly developed by Geely and Keliyuan The dual-planetary row power-split configuration hybrid system represented by "CHS" basically broke the international technological monopoly of Japanese companies. Since entering the "Twelfth Five-Year Plan", domestic enterprises have developed plug-in/extended range vehicles one after another, launching plug-in hybrid models such as BYD Qin, SAIC Roewe 550, and GAC Trumpchi. Among them, the BYD Qin has an acceleration time of 5.9 s per 100 kilometers, and the comprehensive fuel consumption per 100 kilometers is as low as 1.6 L, which generally reaches the international advanced level. The Roewe 550 plug-in model achieves advanced performance indicators such as a pure electric driving range of 58 km, a comprehensive fuel consumption of 2.3 L per 100 kilometers (tested by working condition method), and an acceleration time of 10.2 s per 100 kilometers.

In terms of commercial vehicles, China has basically mastered key technologies such as hybrid vehicle control, high-power motor system, hybrid automatic transmission and control, and APU power generation unit, and has developed a vehicle system with completely independent intellectual property rights. The fuel-saving rate of the direct-drive hybrid system with Chinese technical characteristics reaches 40%. The fuel saving rate of the coaxial parallel hybrid electromechanical coupling system configuration based on the autonomous AMT technology is >30% in the hybrid mode. The new pure electric drive bus power system, which is characterized by the on-board power generation device and the energy storage device jointly driving the motor, forms an integrated platform for various technical routes such as plug-in, range extension, pure electric, and fuel cells. Technical features and advantages of energy diversification and model series.

3) Fuel cell vehicle technology. China's fuel cell car adopts a unique "electric-electric hybrid" power system platform technology solution, with "power system platform vehicle adaptation, electric-electric hybrid energy power control, on-board high-voltage hydrogen storage system, industrial by-product hydrogen purification Utilize" technical features. After entering the "Twelfth Five-Year Plan", the automobile group represented by SAIC formulated a five-year plan for the development of fuel cell vehicles, began to invest a lot of money in the research and development of fuel cell vehicles, and completed the development of the third-generation fuel cell car FCV. In the Bibendum competition, the FCV developed by SAIC ranked third in the fuel cell car category.

China's fuel cell city buses have made important breakthroughs in three major systems (fuel cell/battery hybrid power, electrified chassis, vehicle control) and three major technologies (fuel cell durability, hydrogen-electric safety, and vehicle fuel economy). The hydrogen consumption of the whole vehicle based on the national standard bus cycle is ≤7.5 kg/100 km, reaching the international advanced level. During the "Twelfth Five-Year Plan" period, domestic leading new energy bus companies represented by Yutong Bus fully involved in the research and development of fuel cell buses, developed fuel cell buses that have received national product announcements, and formulated the "Thirteenth Five-Year Plan" fuel cell bus business ization plan. China has basically mastered the system integration technology of 35 MPa hydrogen refueling station. The three key equipment of the hydrogen refueling station: 45 MPa large-capacity hydrogen storage tank, 35 MPa hydrogenation machine and 45 MPa diaphragm compressor have been localized. At the Shanghai World Expo 2010, the large-scale by-product hydrogen purification, transportation, and a small hydrogen refueling network consisting of 2 mobile vehicles (mobile hydrogen refueling stations) and 2 fixed hydrogen refueling stations successfully provided 196 fuel cell tours inside and outside the Expo site. Cars, cars and buses provide high-pressure hydrogen filling services, and their safety and reliability have been tested.

3 Demonstration assessment and promotion and application of new energy vehicles

3.1 Demonstration and promotion process of new energy vehicles

The demonstration and promotion of new energy vehicles in China has gone through three stages.

The first stage (2003-2008): technology verification and technology demonstration project. From 2003 to 2007, with the support of the "Tenth Five-Year" Electric Vehicle Major Project and the "Eleventh Five-Year" Energy-Saving and New Energy Vehicle Major Project, a small-scale electric vehicle demonstration operation and technical verification were carried out, accumulating a large number of technical research and development and Valuable data for upgrades. On this basis, the Development and Reform Commission of the People's Republic of China officially promulgated in November 2007 the management regulations for the implementation of the "Administrative Rules for New Energy Vehicle Production Access" and the "Announcement of Vehicle Manufacturers and Products". Since 2008, it has successively launched new energy vehicle technology demonstration projects in cooperation with major international events such as the Beijing Olympics, the Shanghai World Expo, and the Shenzhen Universiade. Among them, as the starting point and symbol of the science and technology demonstration project, the world's largest demonstration operation of new energy vehicles for the Olympic Games was carried out. A total of 595 energy-saving and new energy vehicles were put into service for the Olympic Games, with a cumulative driving distance of 3.714 million km and a passenger load of 4.417 million. For the first time in the history of the Olympic Games, zero-emission in the central area and low-emission traffic in the surrounding areas have been realized, which has played a starting role in the industrialization of new energy vehicles in China.

The second stage (2009-2012): the first phase of the demonstration and promotion project of 1,000 vehicles in ten cities. Since 2009, China has increased its investment in the demonstration and promotion of new energy vehicles and issued a series of support measures. In 2009, the Ministry of Finance of the People's Republic of China, the Ministry of Science and Technology, the Ministry of Industry and Information Technology, and the Development and Reform Commission jointly launched the "Ten Cities, Thousand Vehicles" demonstration and promotion project of new energy vehicles. In order to encourage the promotion and application of new energy vehicles, in 2009 and 2010, subsidy policies for new energy vehicles in the field of public services and private purchases were successively introduced. In order to improve the performance and industrialization level of new energy vehicle products, in September 2012, the Ministry of Finance, the Ministry of Industry and Information Technology, and the Ministry of Science and Technology of the People's Republic of China organized and implemented the "New Energy Vehicle Industry Technology Innovation Project". From 2009 to 2012, China carried out large-scale demonstration operations of new energy vehicles in 25 pilot cities, and a total of 27,000 new energy vehicles were promoted.

The third stage (2013-2015): the second stage of the demonstration and promotion project of 1,000 vehicles in ten cities. Beginning in 2013, the state's supportive policies for new energy vehicles have been introduced intensively, which has led to the large-scale demonstration and promotion of new energy vehicles. In 2013, the subsidy policy for the second phase of demonstration and promotion projects was introduced. In 2014, the State Council issued four policies and measures to accelerate the development of new energy vehicles. In May 2014, the new energy vehicle decision-making consulting platform - China Electric Vehicle Hundred People's Association was established. Coordinated development between facility construction. Under the leadership of the State Council and the joint efforts of multiple departments, fields and industries, the development of the new energy vehicle market has shown a good momentum of rapid growth. In 2015, the sales volume of new energy vehicles in China reached 330,000, and the proportion of new car sales exceeded 1% for the first time. In 2015, the proportion of new energy vehicles in global sales exceeded 50%. For the first time, China surpassed the United States in sales and ranked first in the world. China has become the world's largest new energy vehicle promotion and application area, and the cumulative promotion of new energy vehicles is close to 500,000. By the end of 2015, 3,600 charging stations and 48,000 charging piles had been built, and a charging and swapping service network had been initially formed.

3.2 Demonstration assessment and industrialization of key components technology

The demonstration and promotion of new energy vehicles in China and the rapid development of the industry stem from the breakthrough in the technical performance of key components and the construction of the industrial chain system. Chinese brand new energy vehicles, which occupy more than 95% of the market share of new energy vehicles, rely on batteries, motors and key electronic control components based on their own core technologies. Moreover, the high-end products among them have been matched with the models developed by top international manufacturers such as BMW of Germany.

1) Power battery. China has established a relatively complete lithium-ion power battery industry chain, forming four major power battery industrialization clusters mainly in the Pearl River Delta, the Yangtze River Delta, the Central Plains and the Beijing-Tianjin region. Lithium-ion power battery cathode materials, anode materials, electrolytes and separators have entered the supply system of international power battery manufacturers. The maturity and scale of the lithium iron phosphate battery industry are leading in the world, and the high specific energy battery using ternary positive electrode material and the fast charging battery using lithium titanate negative electrode material are commercialized on a large scale. Driven by the demand for complete vehicles, the power battery industry for electric vehicles in China has developed rapidly. In 2015, the output reached 20 GW·h. Internationally competitive power battery manufacturers such as BYD and CATL emerged. Among them, BYD built The world's largest lithium-ion power battery production base, Zhejiang Weihong Power's automotive lithium-ion battery systems are exported to Europe on a large scale. China's automotive lithium-ion battery industry is generally in the top three in the world.

2) Motor drive assembly. China's passenger car drive motor system and commercial vehicle drive motor system have formed a large-scale industry. The passenger car drive motor has formed a series of products, which are matched with a variety of domestic passenger cars, and some products have been exported in batches; developed key products such as deep hybrid shunt dual motors, parallel single motors and high-speed bridge drive motors. Used in hybrid and plug-in hybrid and various pure electric vehicles. In terms of commercial vehicle drive motor system products, a series of 65~200 kW electric bus motors and their control system products have been formed, which are respectively applied to 10.5~12 m plug-in hybrid electric bus and 12~13.7 m pure electric bus; A coaxial hybrid dual-motor powertrain product was developed, which was applied to a 12-meter plug-in hybrid electric bus.

Basically form a complete industrial chain of basic components of the motor drive system, including silicon steel sheets, liquid-cooled cast aluminum shells, permanent magnets, etc. China has also established the "Technical Innovation Strategic Alliance for the Whole Industry Chain of Electric Vehicle Electric Drive System" and the "China IGBT Technology Innovation and Industry Alliance". Transformers, automotive connectors and automotive DC/DC converters have formed a large number of typical products, whose indicators and performance are comparable to similar foreign products. Rapid progress has also been made in technical standards, driving the development of China's electric vehicle electric drive system industry.

3.3 Demonstration assessment and industrialization of new energy vehicle technology

With the implementation of national science and technology projects and promotion projects, leading enterprises have accelerated the development of new energy bus products, and formed various technical routes such as hybrid electric buses, pure electric buses, and fuel cell buses. Since 2014, the industrialization process of various models has accelerated, and in 2015, the rapid development of the industrialization of new energy vehicles has been achieved. In 2015, it sold 330,000 new energy vehicles of various types, and 4 companies entered the top 10 sales of new energy vehicles in the world. BYD became the world's largest new energy vehicle manufacturer. China's new energy vehicles, especially new energy commercial vehicles, began to be exported to developed countries on a large scale.

1) New energy commercial vehicles. The production and sales of new energy commercial vehicles have grown rapidly since 2013, and the output in 2015 exceeded 170,000. Among them, the output of new energy buses exceeds 120,000, accounting for more than 80% of the global total, ranking first in the world. New energy buses are the forerunner and main force in the promotion of new energy buses. As of 2015, the number of new energy buses has exceeded 100,000, and now it has accounted for about 19% of the domestic bus population, far ahead of the world. A major breakthrough has been made in the international competitiveness of new energy commercial vehicles, and the industry benchmark enterprise new energy passenger vehicles and assemblies have begun to export on a large scale. At present, the maturity of various hybrid electric bus products is relatively high, and the product performance has been gradually improved after the market pull. Compared with the international benchmark level (25 L/100 km), the fuel consumption of hybrid electric buses in China has increased from 2012. Partially equivalent (2 out of 11 models reached 25 L/100 km), improved to a level surpassed in 2014 (best at 21 L/100 km), and developed a plug-in hybrid product line, technology in 2015 The fuel consumption level of the plug-in hybrid buses of the leading company has been reduced to 19 L/100 km. Pure electric buses have gone through demonstration assessment and technology selection of quick battery replacement, slow charging of large-capacity batteries, and multiple fast charging of small-capacity batteries, and have gradually formed mainstream technologies and models. With the continuous improvement of performance, electric buses are gradually recognized by the market. The operating efficiency has increased from the initial 60% to 93%, and the operating cost has dropped to about 2 yuan/km, which can basically compete with traditional fuel vehicles.

2) New energy passenger vehicles. Since 2010, the production and sales of new energy passenger vehicles have grown rapidly year by year. In 2010, the output of new energy passenger vehicles was only 3,773 units. In 2014, the output increased to 62,000 units. In 2015, the output increased significantly to 205,000 units. The proportion of new energy passenger vehicles in the sales of new passenger vehicles exceeded 1% for the first time. This is a milestone figure, which indicates that new energy passenger vehicles have entered the large-scale promotion from the product introduction stage of the demonstration and promotion stage. stage of industrial growth. In terms of models, pure electric passenger vehicles are dominated by micro and small electric cars, and the proportion is increasing year by year, accounting for more than 85% in 2015. Small electric vehicles are cost-effective and have obvious advantages in energy saving and environmental protection. They are expected to become electric national cars in China. It also has great potential to form an international competitive advantage. Medium and high-level new energy passenger vehicles are mainly plug-in hybrid vehicles, which accounted for more than 82% of sales in 2015. In particular, plug-in SUVs represented by BYD Tang have been welcomed by the market, and sales have soared. Plug-in SUVs are becoming an important development trend, which will play an important role in further enhancing the competitive advantages of Chinese brand SUVs and solving the problems of fuel consumption and emissions of SUVs. It is expected to become a mainstream strategic model of Chinese brands. From the perspective of the actual use of plug-in hybrid electric passenger vehicles, based on the analysis and statistics of big data on vehicles, it is found that with the improvement of charging infrastructure, the proportion of electricity consumption has increased significantly, and the pure electric mileage has accounted for 2% of the total mileage. /3 or more, the energy saving and environmental protection advantages of pure electric drive are emerging.

4 “Thirteenth Five-Year Plan” New Energy Vehicle R&D Prospect

4.1 The background and goals of key special projects for new energy vehicles in the 13th Five-Year Plan

At present, the development of China's auto industry is facing three major challenges and historical tasks. First, the challenge of transforming the auto industry from a big to a strong one. General Secretary Xi Jinping clearly pointed out: "The development of new energy vehicles is the only way for my country to move from a large automobile country to a powerful automobile country"; second, the challenge of automobile exhaust pollution control. The national action plan for air pollution control is forcing the development of zero-emission vehicles; third, the challenges of energy security and low-carbon development brought about by the rapid increase in vehicle ownership. In 2020, the average fuel consumption of passenger car companies will be reduced to 5L per 100 kilometers.

From a global perspective, the technological transformation of new energy vehicles centered on the three major technologies of power electrification, material lightweighting, and vehicle intelligence is undergoing in-depth development. In the next 5 to 10 years, the global automotive industry will usher in restructuring and technological transformation and upgrading important strategic opportunity period.

Overall, the core key technologies of China's new energy vehicles have not been completely broken through, such as new high specific energy, long life, high safety power battery technology, third-generation fuel cell membrane electrode technology, new generation motor-driven power electronics technology, etc.; the supporting system is not enough Perfect, for example, the technology, specification and operation mode of charging infrastructure lag far behind the development of the vehicle market; product performance can not fully meet the market demand, for example, the cost performance of pure electric cars is still lower than that of gasoline cars. Although China's new energy vehicle technology research and development is not late and the speed is not slow, the foundation is not strong, the system is not smooth, and there is still a gap between the international leading level. As a completely open market, the pressure of technological competition is increasing. Accelerating the continuous innovation of new energy vehicles and promoting the technological transformation and upgrading of China's automobile industry are the major strategic needs of China's scientific and technological development.

The overall goals of the "13th Five-Year Plan" new energy vehicle technology innovation are: to implement the "Energy Saving and New Energy Vehicle Industry Development Plan (2012-2020)"; to implement the "pure electric drive" technology transformation strategy for new energy vehicles; "Three verticals and three horizontals" technology system and new energy vehicle research and development system, upgrade the new energy vehicle power system technology platform; seize the opportunity of a new round of technological transformation of new energy vehicles brought about by new energy, new materials, and information technology, and advance research and development. A generation of technology; by 2020, a complete electric vehicle power system technology system and industrial chain will be established, and the technology will support the sound and rapid development of the strategic emerging industry of new energy vehicles.

4.2 R&D layout and key tasks

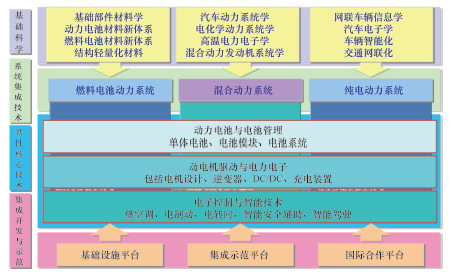

1) R&D layout. The overall layout of the "13th Five-Year" new energy vehicle pilot project is divided into four levels according to the design principle of the whole innovation chain: basic scientific issues, common core technologies, power system technologies, and integrated development and demonstration. Each layer has three modules: three basic scientific issues; "three horizontal" common core technologies; "three vertical" power system technologies; three supporting platforms for integrated development and demonstration (Figure 4).

Figure 4 The special R&D layout of the "13th Five-Year Plan" new energy vehicle pilot project

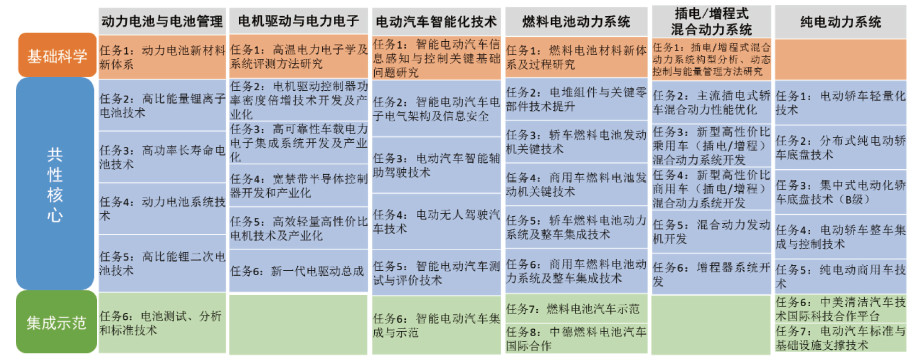

The above 12 modules are combined in series and parallel to form 6 innovation chains (power battery and battery management, motor drive and power electronics, electric vehicle intelligent technology, fuel cell power system, plug-in/extended-range hybrid power system, and pure electric power system), a total of 39 missions were deployed (Figure 5).

Figure 5 The special innovation chain and task deployment of the new energy vehicle pilot

2) Key tasks and goals. Research focus and goals of power battery and management system: Focus on making breakthroughs in high specific energy power battery technology, battery management system, battery safety and other battery system integration technologies. In 2020, the specific energy of mass-produced energy-type power batteries will reach 300(W·h)/kg, the specific energy of the system will be greater than 210(W·h)/kg, the lifespan will reach 1,500 times, and the cost will reach 0.8 yuan (/W· h); The specific energy of the new energy type battery cell for demonstration reaches 400(W·h)/kg, and the specific energy of the new system of the exploratory energy type power battery reaches 500(W·h)/kg; high-power and long-life type The specific power of the power battery reaches 1500 W/kg, and the cycle life reaches 10,000 times.

Motor drive and power electronics R&D focus and goals: to develop high-speed, high-efficiency and lightweight motor systems with a power density of over 4 kW/kg; the specific power of the motor drive controller will reach 17 kW/L by 2020, and the power of a new generation of on-board power electronic converters will be developed. Density >30 kW/L.

The research focus and goal of electric vehicle electronic control and intelligence: to break through the intelligent platform technology of pure electric vehicles, and the intelligent level of electric vehicles to reach SAE level 3 (unmanned driving on structured roads). Demonstration operation of 100-level self-driving smart electric vehicles and 1,000-level network-connected smart electric vehicles will be realized.

Research focus and goals of plug-in/extended-range hybrid power system: to form the mainstream technology route of plug-in electric vehicles with Chinese characteristics and mainstream models that are in the leading position in the world; The fuel saving rate in mixed conditions is greater than 45%; the fuel consumption per 100 kilometers of the plug-in hybrid bus (12m) is less than 16L.

Focus and goals of fuel cell power system research: focus on breakthroughs in high power density, low-cost passenger vehicle fuel cell engine industrialization technology and long-life, high-efficiency commercial vehicle fuel cell engine industrialization technology. By 2020, the volume power density of fuel cell stacks for cars will exceed 3.1 kW/L, and the maximum engine efficiency will reach 55%; the durability of passenger car fuel cell engines will exceed 10,000 hours, and the maximum efficiency will reach 60%. Accelerate the development of hydrogen energy "storage-transport-transport" system research and infrastructure construction, and support the large-scale demonstration and popularization of fuel cell vehicles.

The research focus and goal of pure electric power system: comprehensively improve the comprehensive technical level of pure electric car chassis integration, lightweight body, and vehicle intelligence. Focusing on centralized-drive electric cars, the cost-effectiveness of mainstream electric cars has been comprehensively improved through technological progress. The power consumption per 100 kilometers of A-class cars has been reduced by 20%, reaching 12 kW h (tested by working condition method). Electric cars, the combined cost of purchasing + using after the subsidy is canceled, can compete with fuel vehicles. At the same time, research and development of high-performance electric car technology: for typical models (vehicle length ≥ 4.5 m), the power consumption per 100 kilometers is ≤ 10 kW h (testing by working condition method) and the driving range is ≥400 km (testing by working condition method). Focus on strengthening the technical support capacity of charging infrastructure, improve the level of interconnection, carry out research and development of cutting-edge technologies such as wireless charging and V2G, and realize popularization and application.

5 Conclusion

After the arduous efforts of the three five-year plans, China's new energy vehicles have gone through a development process from foundation, demonstration and assessment to industrialization. The connotation and extension of the "three vertical and three horizontal" R&D layout have been continuously improved. The technology transformation strategy of "driving" has been determined, and the breakthrough of core technology has led to the improvement of product performance. China has become one of the most active regions in the world for the R&D and industrialization of new energy vehicle technology. The development of the new energy vehicle industry is called China by Premier Li Keqiang. The iconic industry of the "new economy" in the industrial field. With the deepening of the new energy vehicle technology transformation of power electrification, lightweight materials, and intelligent vehicles, as a completely open market, China is facing increasing pressure from technological competition. We must do our best to seize the opportunity of a new round of technological transformation of new energy vehicles brought about by new energy, new materials, and information technology, and achieve a comprehensive upgrade of the power system of new energy vehicles, especially to accelerate the realization of revolutionary breakthroughs in power batteries. A sound scientific and technological system supports the sound and rapid development of the new energy automobile industry, and finally realizes the dream of China's automobile industry as a technologically powerful country.

references

[1] Xu Liang. "Tenth Five-Year Plan" National 863 Program Electric Vehicles Major Project Officially Launched [J]. China Science and Technology Industry, 2002(3): 49-50.

[2] Wan Gang. Overview of China's "Tenth Five-Year" Electric Vehicle Major Science and Technology Project Progress [J]. China Science and Technology Industry, 2006(2): 110-117.

[3] The Ministry of Science and Technology's "Tenth Five-Year" Electric Vehicle Major Science and Technology Project passed the acceptance [EB/OL]. 2006-02-20.http://www.most.gov.cn/kjbgz/200602/t20060219_28821.htm.

[4] State Council. Outline of the National Medium- and Long-Term Science and Technology Development Plan (2006-2020) [EB/OL]. 2006-02-20.http://www.gov.cn/gongbao/content/2006/content_240 244 .htm.

[5] Yan Luguang, Chen Junwu. Research on some major issues of sustainable energy development in China [M]. Beijing: Science Press, 2007.

[6] Ouyang Minggao. my country's energy-saving and new energy vehicle technology development strategies and countermeasures [J]. China Science and Technology Industry, 2006(2): 8-13.

[7] Ministry of Science and Technology. “Eleventh Five-Year Plan” 863 Plan for the Implementation of Major Projects of Energy-Saving and New Energy Vehicles (Internal Report) [R]. Beijing: Ministry of Science and Technology, 2006.

[8] Ministry of Science and Technology. “Eleventh Five-Year Plan” 863 Program Energy Saving and New Energy Vehicle Major Projects Passed Acceptance [EB/OL]. 2012-10-09.http://www.most.gov.cn/kjbgz/201210/ t20121008_97083.htm.

[9] State Council. "Twelfth Five-Year" National Strategic Emerging Industry Development Plan [EB/OL]. 2012-07-09.http://www.gov.cn/zwgk/2012-07/20/content_2187770.htm .

[10] State Council. Energy-saving and New Energy Vehicle Industry Development Plan [EB/OL]. 2012-06-28. http://www.nea.gov.cn/2012-07/10/c_131705726.htm.

[11] Hu Jintao. Speech at the 15th Academician Conference of the Chinese Academy of Sciences at the 10th Academician Conference of the Chinese Academy of Engineering [EB/OL]. 2010-06-07.http://www.gov.cn/ldhd/2010- 06/07/content_1622343.htm.

[12] Xi Jinping. The development of new energy vehicles is the only way to become an automobile power [EB/OL]. 2014- 05- 24. http://news.xinhuanet.com/2014- 05/24/c_1110843312.htm.

[13] Ministry of Science and Technology. "Twelfth Five-Year Plan" for Electric Vehicle Technology Development [EB/OL]. 2012-03-27. http://www.most.gov.cn/tztg/201204/t20120420_93807 .htm.

Scan the QR code to read on your phone

Recommended news

Message consultation

Beijing Headquarter/R & D Center:

Beijing KeyPower Technologies Co., Ltd.

Address: 9B, Diantong Innovative Plaza, No. 7, Jiuxianqiao North Road, Chaoyang District, Beijing

Phone: 400 666 4009-1(China)

Email: office@key-power.com.cn

Suzhou Manufacturing Base:

Suzhou KeyPower Technologies Co., Ltd.

Address: Building 17, Dongjing Industrial Workshop, Suzhou Industrial Park, Suzhou

Phone: 400 666 4009-2 (China)

Email: Plant@key-power.com.cn

Liuzhou Manufacturing Base:

Liuzhou KeyPower Technologies Co., Ltd.

Address: Building 3, Intelligent Grid Industrial Park Phase Ⅱ, Northern Ecological New Area, Liuzhou

Phone: 400 666 4009-4 (China)

Email: PlantLZ@key-power.com.cn

Contact Us: